PROCUREMENT SUPPLY CHAIN MANAGEMENT

INTRODUCTION:

Industrial and Oilfield division of PETECS was established by a group of Specialists who are experts in the field of petrochemical raw materials, industrial chemicals and water treatment chemicals.

The Company is oriented towards sales of chemicals in Middle East, North Africa, East Europe and Asian countries.

The fundamental principle of our INDUSTRIAL & OILFIELD CHEMICAL DIVISION is to provide value, innovation and smart solutions under tough and competitive market conditions; providing convenience, one-stop-shop facility, consistency in product quality, competitiveness in price and timeliness in delivery to our customers. Our goal is to open new markets and establish convenient chain of logistics and services for sourcing and supply of chemicals.

PETECS is a well-established, dynamic and professionally managed group, engaged in the business of sourcing and application of quality chemicals. We are focused towards providing complete business solutions to our vast clientele in Europe, Middle East, North Africa and Asia. We offer our partners in business a relationship based on transparency and commitment and we always put in place all necessary means and measures to ensure success.

VISION:

Our vision is to be “PARTNERS IN PERFORMANCE” with like-minded clients and ambitious organizations and contribute towards producing reliably, safely and effectively.

Building on years of knowledge and innovation in oilfield chemical services, experts properly diagnose potential risks, implement the right treatment, and continue to optimize performance to keep your production flowing—reliably, safely and effectively.

ROLES & RESPONSIBILITIES

Proactively manage risks and keep production flowing.

Production blockages can be caused by a variety of sources, including paraffin, asphaltenes, scale, and hydrates. All of these lead to costly issues like production loss, downtime, equipment repairs, and more.

The good news? You don't have to wait until there's a problem to take action. Flow assurance chemical solutions help you proactively mitigate these risks before they become big problems. From greenfield development projects to mature field operations, we help you address flow challenges throughout the production lifecycle to avoid startup delays and well shut-ins and increase the profitability of your producing assets.

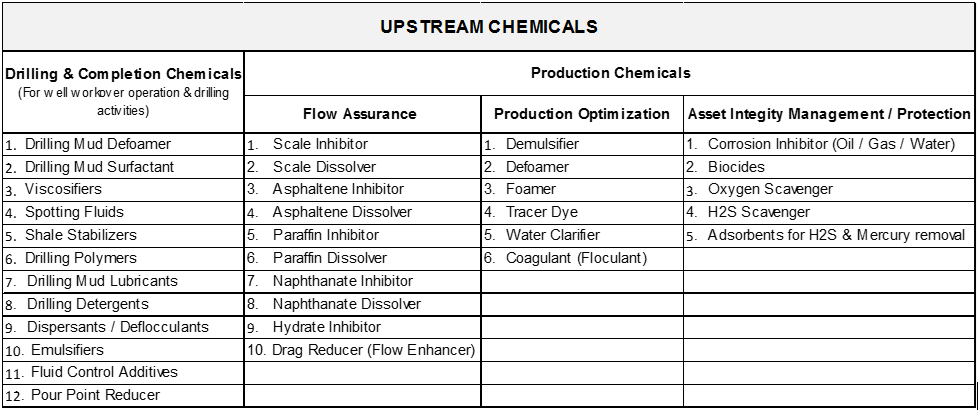

Flow assurance solutions include:

Ensure continuous production and lower maintenance costs

Mineral scale deposition is a major flow assurance problem for oil and gas operators. Two of the most common types of scales found in the oilfield are calcium carbonate, which is primarily caused by depressurization, and barium sulfate, which is primarily caused by incompatibility between the formation fluids and the injection water. But there are other types of scale as well – all of which can impede flow and impact performance of operational equipment, if not properly treated.

Scale creates headaches for operators who, many times, must shut down production to remediate scale deposition through costly removal and repairs to equipment, such as electrical submersible pumps. In the process, they lose valuable production revenue.

Mineral scale control services cost-effectively prevent and control scale buildup, enhancing flow assurance for production systems. Our chemical solutions help you meet any scale challenge, including tough barite, silicate, and iron-sulfide scales. Our experts offer a comprehensive and interactive approach to mineral scale control:

Maximize production and throughput

Our production optimization services ensure top performance from new and mature assets. We maximize throughput at fluids separation facilities; you can produce cost-effectively and safer at or above nameplate specifications. In mature fields, we reinvigorate declining production and keep assets producing profitably.

Protect the environment

We understand how to maximize oil and gas production and throughput. Our cost-effective and customized chemical treatment solutions also protect the environment. These solutions reduce energy demand in separation processes, minimizing oil-in-water emulsions and getting more life from existing infrastructure.

Maximize profit

From green field to mature, bitumen/heavy oil to condensate, onshore to deepwater, we maximize profit through improved operations by

FLUIDS SEPARATION

Our fluids-separation technology delivers on-spec crude oil quickly and efficiently by breaking oilfield emulsions.

Chemical Solutions for Near-Wellbore Damage

We provide chemicals for near-wellbore damage which help improve well productivity by delivering a cost-effective solution to combat restricted flow caused by paraffin, asphaltenes, scale, and emulsions.

Increase production throughput and reduce energy requirements

Our fluids-separation technologies deliver on-spec crude oil quickly and efficiently by breaking oilfield emulsions. Superior fluids separation keeps production at or above nameplate capacity, prevents off-spec oil, and minimizes oil losses.

Efficiently break oilfield emulsions

Breaking oilfield emulsions efficiently is critical for meeting production targets and export crude specifications. Our demulsifiers offer rapid water drop, distinct oil/water interface, clean effluent water for disposal or reinjection, low salt in crude, asphaltene stabilization, and environmental regulatory compliance.

Correct poor water quality

Fine oil dispersions and reverse emulsions reduce the quality of produced water. Many operational factors that cause poor water quality often can be corrected by proper maintenance, operations, and demulsifier selection. When these are not enough, water clarifier treatments can reduce oil losses dramatically as they improve water quality while decreasing oiling out of filter media, improving deteriorating injection well profiles, and facilitating water disposal that meets governmental and corporate regulations.

PRODUCT LISTING

“Partners in Performance”