Stimulation and Flow Assurance

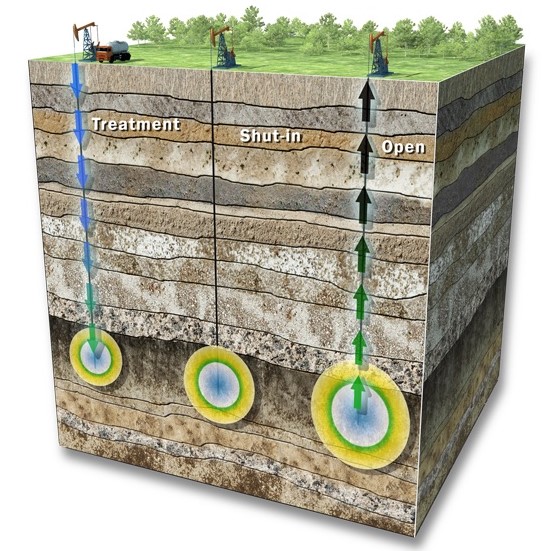

Acid Stimulation:

A treatment with a stimulation fluid containing a reactive acid, used primarily to remove drilling damage and increase permeability near the well-bore.

In sandstone formations, the acid reacts with the soluble materials, such as drilling mud, formation matrix and enlarges the pore spaces. Effectively this is a cleaning process, attempting to return porosity and permeability to its original state.

In carbonate formations, the acid dissolves the entire formation matrix. The destruction of the matrix forms wormholes (highly conductive paths), which improve the formation permeability and enables enhanced production.

Matrix acidizing operations are performed at low rates and treatment pressures below the frac pressure of the formation. This enables the acid to penetrate the formation and increase the depth of treatment while avoiding damage to the reservoir formation.

Biotech Enhanced Oil Recovery (EOR)

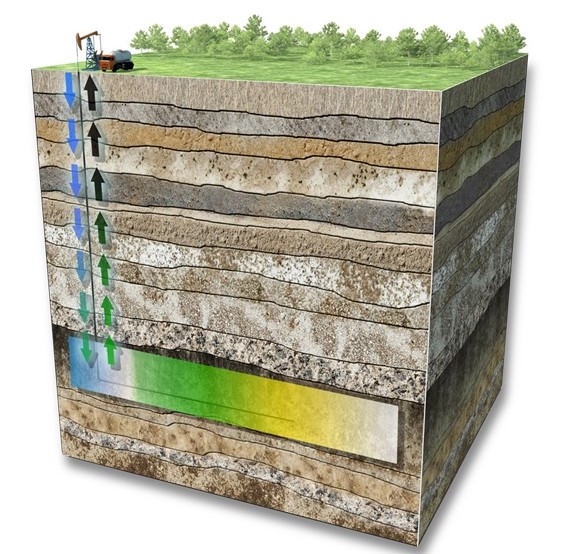

BERO™ (Biosurfactant Enzyme for Recovery of Oil) is a bio-enzyme with non-activity preparation and water-soluble. It utilizes modern bioengineering technologies such as genetic engineering, cell engineering and enzyme engineering and can efficiently release hydrocarbon (oil) on the surfaces of solid particles. After being injected into a oil reservoir, BERO™ biosurfactant can rapidly strip wax and asphalt crystallized and accumulated on rock particles in the area of a reservoir close to well and part of BERO™ biosurfactant adheres to rock surface to make the wettability of the rock become water-wetting, lower the flowing resistance of crude oil in formation voids, thus releasing crude oil from rock particle surface and being separated out from micropores. BERO™ entering into water can be transported to the area further than the surrounding area of sandstone formation and form new oil outlet passages in sandstone formation so as to clean and wash the oil reservoir, plugging agents removal and injection reduction of water injection well, plugging removal and stimulation, oil displacement and improving oil recovery rate.

Single Well

Cause of formation plugging from the following aspects:

Waxy, asphalt material with the oil flow, pressure and temperature, crystallization, deposition in the wall rock oil channel, in the near wellbore are formed by oil passage.

After a mass production, the solid particle volume increases in crude oil, resulting in formation plugging oil holes.

High shale content in formation due to hydration expansion, reduces the formation permeability.

In view of the above reasons for the formation plugging, BERO™ enzymes can be made extremely remarkable effect.

Single Well

Cause of formation plugging from the following aspects:

Waxy, asphalt material with the oil flow, pressure and temperature, crystallization, deposition in the wall rock oil channel, in the near wellbore are formed by oil passage.

After a mass production, the solid particle volume increases in crude oil, resulting in formation plugging oil holes.

High shale content in formation due to hydration expansion, reduces the formation permeability.

In view of the above reasons for the formation plugging, BERO™ enzymes can be made extremely remarkable effect.

Waterflooding

BERO™ Enzyme has the same density with water, totally soluble in water. It will rapidly displace the crude oil that is attached to the rocks in the section where it passes through when the injected water carries it for movement. Meanwhile, part of BERO™ Enzyme will attach to the rock surface and form a new oil flow channel in the formation. There will be no cause Pore plugging problem as it will not produce any derivatives.